Use the power of compressed air to clear blockages from the inner walls of kilns, silos, hoppers, and chutes.

Air cannons are specialized devices used to prevent and eliminate arching, silo blockage, wall adhesion, and material retention in various types of silos, hoppers, and pipe branches. They are suitable for cylindrical silos, hoppers, pipes, and flat-bottomed piles made of various steel, concrete, and other materials.

Air cannons are widely used in thermal power plants, coal mines and underground coal bins, coal washing plants, cement plants, concrete processing plants, foundries, fertilizer plants, coking plants, gas plants, chemical plants, aluminum plants, alkali plants, steel plants, mines, ports, food, grain, feed processing plants, boilers, pharmaceutical factories, and oil pipelines, etc., where important bulk materials are stored and transported. This equipment is widely used and plays a very important role in industrial production.

When bulk materials accumulate in kilns, silos, coal bunkers, hoppers, chutes, and other equipment, and cease to flow due to blockages and rat holes, the ideal way to keep them flowing continuously is to use pressure, volume, and impact-adjustable air cannons manufactured by Gongshen Company. Air cannons are extremely effective for materials such as coal, cement, and aggregates, especially when they retain less moisture and become sticky.

Gongshen Company offers a range of air cannons. Whether your application requires more frequent, shorter bursts of powerful air every few seconds, we have a product to meet your needs. In addition, we also offer multi-valve products that inject air through pipes or hoses at multiple injection points to adapt to confined spaces.

Air cannons, also known as air assistors, arch breakers, and unblocking devices, use a strong airflow of suddenly ejected compressed gas, exceeding Mach 1 (the speed of sound), to directly impact the blocked area of stored bulk materials. This sudden release of expansion shock waves overcomes the static friction of the material, allowing the material in the container to flow again.

Working principle

It utilizes aerodynamic principles, with air as the working medium. A differential pressure device and a rapidly venting valve capable of automatic control instantly convert the air pressure energy into air jet kinetic energy, generating a powerful impact force. It is an ideal cleaning, pollution-free, and low-energy-consumption unblocking and soot blowing device.

As a powerful device for clearing blockages in silos and pipes, the operation of an air cannon requires the combined action of related components, mainly including: the air cannon body (including the jetting component), a three-way solenoid valve, an air cannon controller, and an air cannon blowing pipe.

1. Submerged pulse valve: A diaphragm-type submerged pulse valve is used to automatically start the air cannon;

2. Air cannon controller: A microcontroller with timing settings is used to control the air cannon action interval or control the action sequence of multiple air cannons;

3. Air cannon blowing pipe: For the situation where, after the air cannon breaks the material bridge, the material slides down along the barrel wall (which can lead to adhesion or soiling of the barrel wall);

4. Air piping accessories: To ensure the good operation of the air cannon and extend its service life, an air filter, pressure regulator, and oil mist lubricator should be used;

5. Air pipe one-way check valve: To prevent pressure reduction due to problems in the inflation pipeline;

6. Installation and fixing accessories: When the strength of the material barrel body is insufficient to support the weight of the air cannon, the air cannon needs to be effectively bound and fixed;

7. Safety steel cable;

8. Manual ball valve: A two-way manual ball valve is used to control the total gas source of the air supply pipeline.

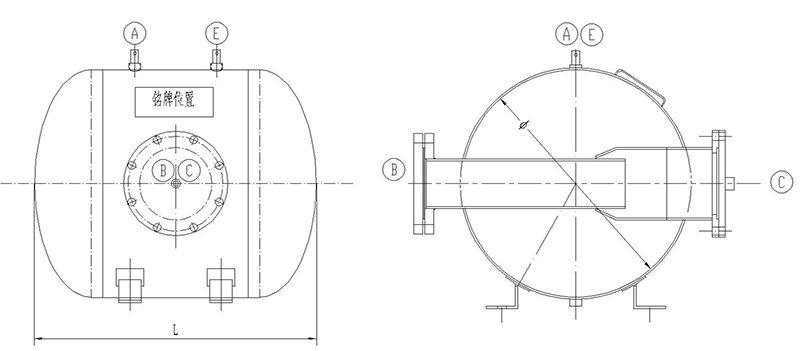

GS-KQP Air Cannon Parameter Table (0.4-0.8MPa)

Model | Volume | L (mm) | φ (mm) | A (mm) | B (mm) | C (mm) | D (mm) | E (mm) | Working Pressure MPa | Working Temperature ℃ | Impact Force N | Explosion Energy J | Weight kg |

GS-KQP-B-30 | 30L | 463 | 325 | G1/2" | 57 | 89 | G1/2" | G1/2" | 0.4~0.8 | -19~120 | 1200~3000 | 6800 | 38 |

GS-KQP-B-50 | 50L | 479 | 400 | G1/2" | 57 | 89 | G1/2" | G1/2" | 0.4~0.8 | -19~120 | 1400~4200 | 8800 | 42.5 |

GS-KQP-B-75 | 75L | 554 | 450 | G1/2" | 108 | 159 | G1/2" | G1/2" | 0.4~0.8 | -19~120 | 2500~6500 | 10200 | 47.5 |

GS-KQP-B-100 | 100L | 628 | 500 | G1/2" | 108 | 159 | G1/2" | G1/2" | 0.4~0.8 | -19~120 | 3000~8000 | 14300 | 75.4 |

GS-KQP-B-150 | 150L | 643 | 600 | G1/2" | 108 | 159 | G1/2" | G1/2" | 0.4~0.8 | -19~120 | 4500~10000 | 20400 | 85.3 |

GS-KQP-B-200 | 200L | 735 | 650 | G1/2" | 108 | 159 | G1/2" | G1/2" | 0.4~0.8 | -19~120 | 5000~15000 | 25800 | 107.6 |

GS-KQP-B-300 | 300L | 837 | 750 | G1/2" | 108 | 159 | G1/2" | G1/2" | 0.4~0.8 | -19~120 | 7800~19200 | 68000 | 125.4 |

GS-KQP-B-500 | 500L | 1035 | 850 | G1/2" | 133 | 219 | G1/2" | G1/2" | 0.4~0.8 | -19~120 | 13800~28700 | 88000 | 193.3 |

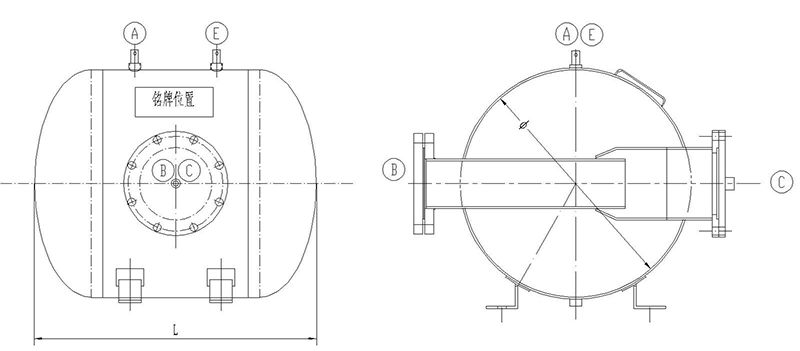

GS-KQP Air Cannon Parameter Table (0.8-1.6MPa)

Model | Volume | L (mm) | φ (mm) | A (mm) | B (mm) | C (mm) | D (mm) | E (mm) | Working Pressure MPa | Working Temperature ℃ | Impact Force N | Explosion Energy J | Weight kg |

GS-KQP-B-30 | 30L | 463 | 325 | G1/2" | 57 | 89 | G1/2" | G1/2" | 0.8~1.6 | -19~120 | 1600~4000 | 9000 | 60 |

GS-KQP-B-50 | 50L | 479 | 400 | G1/2" | 57 | 89 | G1/2" | G1/2" | 0.8~1.6 | -19~120 | 1800~5600 | 11700 | 72 |

GS-KQP-B-75 | 75L | 554 | 450 | G1/2" | 108 | 159 | G1/2" | G1/2" | 0.8~1.6 | -19~120 | 3300~8600 | 13600 | 87 |

GS-KQP-B-100 | 100L | 628 | 500 | G1/2" | 108 | 159 | G1/2" | G1/2" | 0.8~1.6 | -19~120 | 4000~10000 | 19000 | 102 |

GS-KQP-B-150 | 150L | 643 | 600 | G1/2" | 108 | 159 | G1/2" | G1/2" | 0.8~1.6 | -19~120 | 6000~13000 | 27200 | 120 |

GS-KQP-B-200 | 200L | 735 | 650 | G1/2" | 108 | 159 | G1/2" | G1/2" | 0.8~1.6 | -19~120 | 6600~20000 | 34400 | 146 |

GS-KQP-B-300 | 300L | 837 | 750 | G1/2" | 108 | 159 | G1/2" | G1/2" | 0.8~1.6 | -19~120 | 10400~25000 | 90000 | 173 |

GS-KQP-B-500 | 500L | 1035 | 850 | G1/2" | 133 | 219 | G1/2" | G1/2" | 0.8~1.6 | -19~120 | 18400~38200 | 117000 | 260 |

Keywords:

Air Cannon

Air Cannon

Contact Us

Product Classification

Related Products

Complete Set of Equipment for Gas Explosion

Circulating Fluidized Bed Boiler